Retailers’ demand for consistent chicken portion sizes is making uniformity in poultry meat ever more important. Modern hatcheries therefore aim to supply uniform day-old chicks to the production chain. A key factor is the hatch window: a shorter window leads to better chick uniformity. This article discusses the role of the hatch window, practical approaches to monitoring it, and its impact on uniformity and the economic success of hatcheries, farmers and processors.

Definition of the hatch window

The term 'hatch window' refers to the time span during which chicks come out of their eggs. In natural incubation, it is described as the period between the first and last chicks hatching within a single clutch. In commercial incubation, however, determining the exact timing of these events is challenging. Therefore, in practice, the hatch window is estimated as the period between the hatching of the first chicks – typically around the first 1-2% beginning to emerge – and the moment the full batch is dry, active and ready for pulling.

In commercial incubation, there are two main factors that influence the duration of the hatch window:

1. Embryo similarity from the start

All embryos making up one commercial egg batch should be as similar as possible. This is mainly determined by the composition of the egg batch and by the conditions the eggs are subjected to from collection on the farm to the start of incubation.

- Breeder farm: genetic line, flock age, egg size and egg weight.

- Handling of the eggs: circumstances on the farm, in transport and during storage.

- Conditions of the eggs: number of storage days, state of early embryonic development and pre-incubation treatments.

2. Incubation conditions

Once the eggs are placed inside the single-stage incubator, the incubation technology must ensure that all embryos develop and grow at a similar rate. This requires continuous adjustments to setter and hatcher conditions, aligned with the changing needs of the embryos throughout incubation – just as it would happen in nature.

- Correct heat treatment and proper egg preheating, so all embryos start incubation at the same developmental stage.

- Dedicated incubation program, tailored to breed, flock age, egg age etc.

- Continuous fine-tuning of setter and hatcher conditions, aligned with the changing needs of the embryos. This is especially critical during the complex hatching phase, when the embryos undergo key physiological changes, transitioning from chorioallantoic to pulmonary respiration, in parallel with yolk sac retraction. To support this process, hatcher conditions must be precisely synchronized with embryonic development.

A hatch window is considered narrow when the time difference between the first chicks hatched and the last chicks hatched is no more than 24-30 hours. This indicates that the chicks have developed at a similar rate and hatched relatively simultaneously, even with a large batch of 20-40 thousand eggs in one single hatcher.

The moment hatchery operators remove the chicks from the hatcher is called 'take-off' or 'pull time'.

- If the timing was correct, nearly all chicks will be standing, active, dry and fluffy. Their legs will appear well-hydrated and shiny. A good guideline is to have less than 5% of the chicks with damp neck feathers.

- There will always be a few late chicks, but waiting for them negatively impacts the chicks that have already hatched.

Ways to assess the hatch window in commercial hatcheries

There are several methods to investigate the hatch window in commercial hatcheries. Each of these methods has its specifics and considerations to take into account.

1. Estimating the hatch window by assessing embryonic uniformity at transfer

One technique to assess the hatch window is during a breakout session at transfer, by identifying whether the embryonic stage per flock is correctly aligned.

- Select a representative number of eggs from each flock, from different trolley positions and from top, middle and bottom trays.

- Evaluate the uniformity in yolk sac absorption and key physical traits - such as embryo size and positioning - to accurately assess synchronization of embryonic development.

- This method allows to investigate if embryos from the same flock show uniform development, providing an early indication of whether the hatch window is likely to be narrow or wide.

- Although labour-intensive due to embryo sacrifice, it provides good insight into embryonic uniformity and represents an indirect estimate of the hatch window.

2. Counting hatched chicks at specific times

Another method for monitoring the hatch window is to open the hatcher and verify the number of chicks hatched.

- Select at least three hatcher baskets (top, middle and bottom positions) from different locations (e.g. front row, back row, near the wall and near the pulsator). This ensures a representative sample and helps eliminate potential influences caused by positional differences within the machine.

- Count the hatched chicks in each selected basket, record the data and return the baskets to their original position.

- This method provides direct data on the number of chicks hatched at a specific moment. To gain insight into the hatching progress, it must be repeated a few times, usually at 12-hour intervals from -36 hours until pull time.

- Applying it across all hatchers poses logistical challenges. It also requires opening the hatcher doors, which can influence internal conditions and affect hatch results.

3. Analysing the humidity curve during the hatching phase

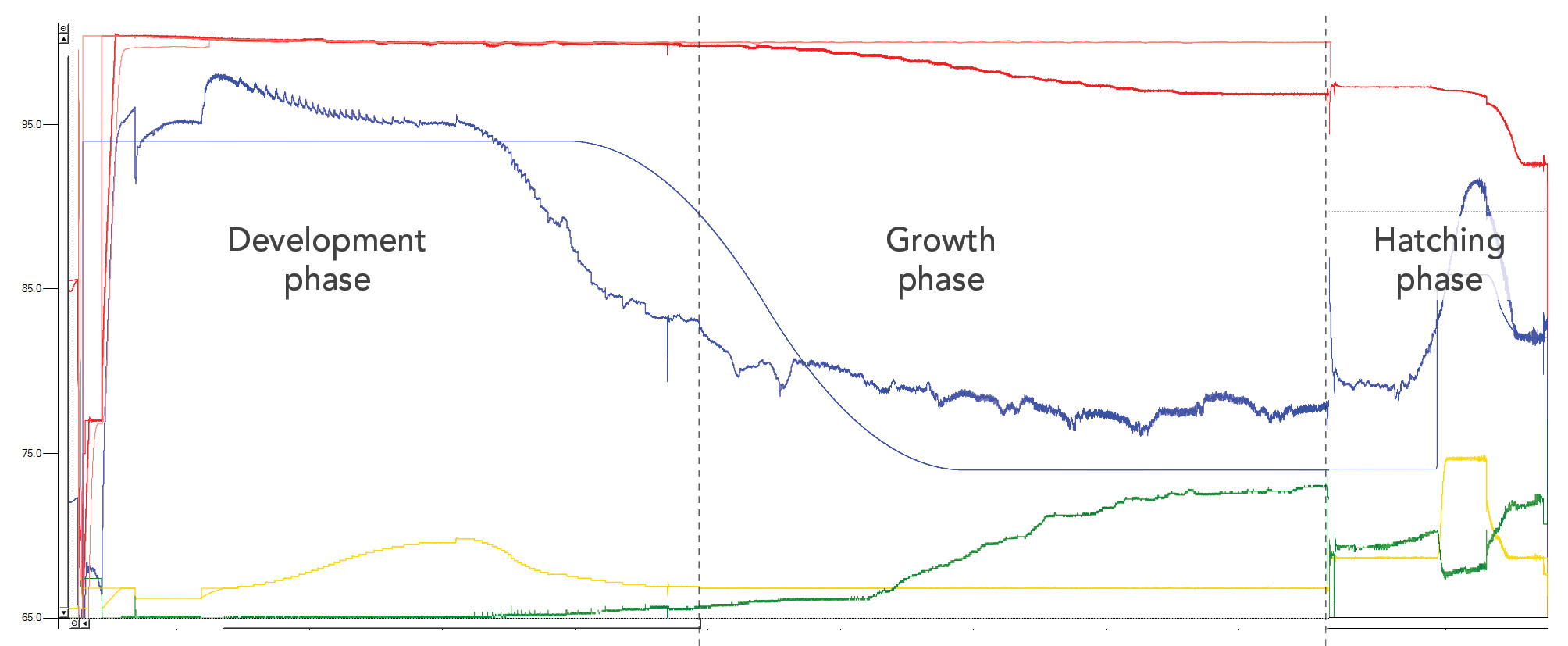

A third way to monitor the hatch window is by analysing the humidity curve in the hatcher. The onset of hatching is marked by a rise in humidity as embryos start to externally pip and hatch, releasing moisture into the hatcher environment. This humidity increase continues as more chicks emerge, peaking when the majority have hatched. The shape of the curve reflects how uniformly the hatch has taken place. Petersime uses this principle to monitor the hatch window.

- The humidity sensor in Petersime hatchers continuously monitors the humidity level throughout the hatching phase, with the humidity peak serving as a reliable indicator that the majority of chicks have hatched.

- This method provides an indirect yet accurate estimate of the start and end of hatching, without interrupting the process. The humidity curve accurately reflects the hatching status of the entire population in the hatcher.

- Data can be collected across all hatchers and cycles for comparative analysis. For customers using Eagle Trax™, hatching cycles can be overlaid to easily compare humidity curves from different hatchers and visually obtain a direct comparison between hatch windows.

Part of Petersime’s Eagle Trax™ cloud-based hatchery software, the Basic module helps hatchery managers dive deeper into their incubation cycle data. It enables them to:

- Thoroughly analyse and compare incubator cycles, whether from the same incubator or from different ones;

- Combine setter and hatcher cycles into one clear graph for a full-cycle overview;

- Use the handy overlay function to compare cycles and hatch windows;

- And much more, based on the specific set-up and needs of each hatchery.

Hatch window control: why chick uniformity matters for the industry

The poultry industry benefits significantly from working with uniform day-old chicks supplied by hatcheries. It's crucial to consider the consequences of a lack of chick uniformity, as it affects the results at both the grow-out farm and the processing plant as well as the ability to meet specific retailer expectations.

1. Grow-out farm

A wide hatch window leads to a greater variation in chick sizes. On the farm, chicks that lag in growth struggle to compete for feed and water. If this lack of uniformity persists until the processing stage, small chicks will not be collected and will remain on the farm for the grower to deal with. Conversely, if day-old chicks arrive at the farm with similar size and quality, it promotes synchronised feed and water intake, enhancing growth uniformity.

2. Processing plant

Lack of uniformity becomes even more evident at the processing plant, where small chicks face multiple risks. They may miss the stunner, leading to improper bleeding and rejection, or slip from the shackles during plucking, risking being lost as waste. In scalding, undersized birds over-scald easily, degrading protein and meat quality. Processing machinery that is calibrated for a set weight range struggles with extremes: small chicks sustain more damage from cutters and eviscerators.

3. Retailer

It is the customers of the processing plants who precisely determine the product requirements for chicken portions and whole chickens. These requirements can only be met by broilers of a particular weight range. As a result, broilers that do not fit this 'ideal size' range are processed less efficiently and are therefore less desirable.

In summary

When brooding, the mother hen instinctively finetunes the temperature, oxygen and humidity levels to create the optimal incubation environment for her clutch of eggs and hatch them simultaneously. For commercial hatcheries, the main objective concerning the hatch window is to replicate the conditions the hen provides in her nest, ensuring the time between the hatching of the first and last chick is as short as possible. This is important because the size of the hatch window greatly affects chick uniformity and, as such, the economic success of hatcheries, farmers and processors.

The natural brooding process is the starting point of Petersime’s philosophy. Our Embryo-Response Incubation™ technology emulates the experience the embryo has in the nest. It constantly monitors embryo behaviour, automatically adapting the incubation environment to the needs of each specific batch of eggs to maximize incubation results. Please don’t hesitate to contact us for more information.