The COVID-19 pandemic is causing chick order disruptions, confronting hatcheries with having to store more eggs for longer periods. It is well-known that storing eggs for multiple days causes a decline in hatchability and egg quality. In this article, we reach out with a solution to reduce the negative effects of prolonged egg storage: a dedicated incubator to precisely apply heat treatment cycles during egg storage.

Challenging market conditions

The poultry sector is in a challenging situation and will likely remain so with the continuation of the COVID-19 pandemic. The temporary closure of restaurants in many countries has been leading to sudden drops in poultry meat and table egg demands. Consequently, incubation egg volumes show fluctuations, which poses great challenges to broiler and layer planning. As a result, many hatcheries are confronted with eggs that must be stored much longer than usual, in certain cases reaching 14 days or more.

Drawbacks of long egg storage

In the egg holding room, eggs are kept at or under a so-called threshold temperature or physiological zero for development. At this temperature, embryonic development is slowed down. However, it is well-known that storing eggs for multiple days causes a decline in hatchability and egg quality. Subsequently, chick quality will deteriorate, incubation time will increase and post-hatch performance will suffer. Add to this the logistical constraints that hatcheries must consider when confronted with extended egg storage and diverse egg ages. The staff needs extra time to deal with the variations that come with the incubation of long-stored eggs, such as adjusting incubation times, preheating programmes, take-off times, etc.

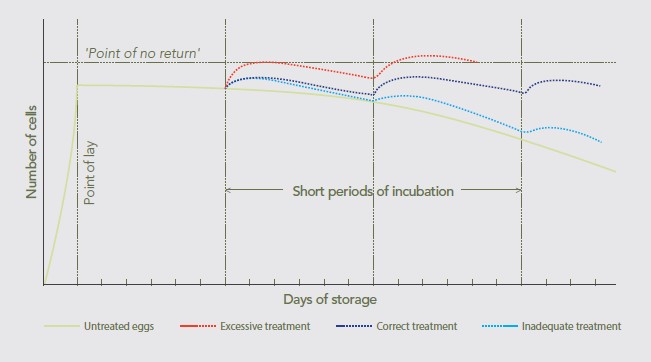

One way to reduce the impact of long egg storage times is applying heat treatment cycles (often also referred to as SPIDES) during egg storage. In nature, a mother hen lays one egg every day, until her nest is complete. As a result, the older eggs are warmed each time the hen returns to her nest to lay the next egg. These eggs thus undergo a short period of incubation every day, which restores their viability. In a commercial hatchery, the same effect can be reached by applying heat treatment cycles during the storage time.

Precise application of heat treatment cycles

Heat treatment during storage has great potential in restoring the hatchability and even improving chick quality. It is crucial, however, to accurately control the key incubation parameters, as inadequate application of the technique will result in suboptimal results or perhaps even lead to major losses.

Therefore, Petersime offers the X-Streamer™ Re-Store, a dedicated incubator that is specially engineered and programmed to precisely apply heat treatment cycles. It ensures the precise measurement and control of the eggshell temperature in the incubator, as well as controlled and uniform warm-up and cool-down phases of the eggs – two key elements to achieve consistent gains. All values and setpoints are automatically adjusted to optimize the process according to the needs of the specific batch of eggs. This makes the X-Streamer™ Re-Store the perfect solution for hatcheries to optimally apply the SPIDES treatment and restore the hatchability of long-stored eggs.

Proven performance

Petersime has run several large-scale trials with Re-Store and the results have proven to be significantly positive. The solution shows its effectiveness around the world in many hatcheries with different egg species and varying egg ages:

- Better hatch and post-hatch performance of broilers

- Reduced early, mid and late embryonic death

- Improved turkey egg performance

- Enhanced hatch and post-hatch performance of layers

Petersime is happy to help you find the Re-Store incubator model that is best suited for your business. Please don’t hesitate to contact us for more information.

Interesting topics